CRYOGENIC LIQUID STORAGE TANKS

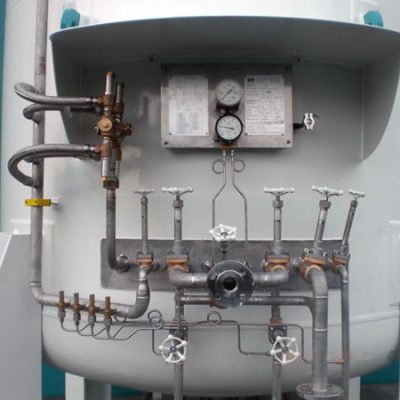

Oxyplants India Pvt. Ltd. offers a full line of cryogenic liquid storage tanks for liquid oxygen (LOX), liquid nitrogen (LIN), liquid argon (LAR) and liquid carbon dioxide (CO2) service. Tanks are produced to store the inner gas, at -196 ºC or at a less temperature, depending on different design parameters. The cryogenic storage tanks, pressure vessels, and vaporizers are manufactured in India As a design standard it is used CODE 2000, EN 13458, EN 13530, ADR 2009 and ASME Section VIII Division 1 and CGA-341 codes and standards. It is also possible to design products in different standards according to the requests of customers.

The cryogenic tank consists of two tanks Outer & Inner Tank. The inner tank is made out of stainless steel 304L (X5 CrNi 18-10) & design code EN13458, While the outer one is made of CARBON STEEL & design code EN13458. The gap between tanks is filled with Perlite aggregation and super insulation by vacuum technology. The manufacturing processes of the tanks are as follows: Tanks are produced to store the inner gas, at -196 ºC or at a less temperature, depending on different design parameters. LIN, LOX, and LAR cryogenic storage tank capacities range from 300 gallons to 80,000 gallons (50 tons). Vaporizers are also available in a wide range of capacities - from 700 SCFH (20 Nm3/h) to 35,000 SCFH (1000) Nm3/h per unit. Also supplies Liquid CO2 storage tanks in sizes holding 3 to 50 tons of products.

- High Performance & extended hold time for lower life cycle cost.

- All welded stainless steel piping modules

- Highest grade components for low to zero maintenance

- Provision for transmitter mounting and telemetry

- Multiple anchor bolt provisions to meet all seismic zones.

- Cold stretched inner vessel.

- Heavy duty bronze valves with extended bonnets

- Long lasting high quality surface finish & paint.

- Flow Diverter valve with 2 relief valves as standard.

- Stainless Steel body cryogenic valves.

- New easy access multi-functional single setting cryo regulator for pressure building & economizer.

- Efficient aluminum star fin design pressure building coil.

- Tanks of 24 kg/cm² MAWP comes with LCO₂ & LN₂O service.

|

CODES: |

ASME Section - VIII DIV-1 / EN - 13458 / I.S. 2825 ETC WITH SMPV (U) Rules |

|

DESIGN PRESSURE: |

18 Kg/cm2 |

|

WORKING PRESSURE : |

1 Kg to 15 Kg/cm2 |

|

DESIGN TEMPERATURE |

-196oC (-320oF) + 65oC |

|

CAPACITY: |

1000 ltrs to 50000 ltrs working vol. |

|

VAPOUR SPACE: |

3 to 5 % of working capacity |

|

NER (Normal Evaporation Loss ) O2 |

STP Condition |

|

NER (Normal Evaporation Loss ) N2 |

STP Condition |

|

NER (Normal Evaporation Loss ) Ar |

STP Condition |

|

STANDARD DESIGNS: |

6000 Ltrs, 7000 Ltrs, 8000 Ltrs, 10000 Ltrs, 12000 Ltrs & 15000 Ltrs, Capacities with medium & High Pressures. |

CRYOGENIC LIQUID TRANSPORT TANKS:

Oxyplants India Pvt. Ltd. offers a full line of liquid transport tanks for liquid oxygen (LOX), liquid nitrogen (LIN), liquid argon (LAR) and liquid carbon dioxide (CO2) service. Tanks are produced to store the inner gas, at -196 ºC or at a less temperature, depending on different design parameters. The tanks are manufactured in India As a design standard it is used CODE 2002, EN 13458, EN 13530, ADR 2009 and ASME Section VIII Division 1 and CGA-341 codes and standards. It is also possible to design products in different standards according to the requests of customers.

Cryogenic Liquid Transportation Tanks are used for the storage and transportation of the gases in liquid form. These Tanks are produced to store liquid and gas according to the pressure condition requests of the customers. The inner tank is made out of stainless steel 304L (X5CrNi18-10 AS PER DIN 10028-7 OR EQU) & design code EN 13530 - 2002, while the outer one is made out of CARBON STEEL & design code EN 13530:2002. The isolation between tanks is provided by super insulated by vacuum technology. The manufacturing processes of the tanks are as follows: Tanks are produced to store the inner gas, at -196 ºC or at a less temperature, depending on different design parameters. LIN, LOX, and LAR Liquid Transportation Tanks capacities range from 300 gallons to 10,000 gallons (30 tons).

- Intelligently automated & Reliable Cryogenic Delivery System.

- Equipped with hydraulic powered centrifugal pump system featuring dual fill modes.

- Larger fire hose for bulk filling.

- The automation is controlled by a rugged off the Shelf PLC

- Stop capability for terminating the fill of liquid cylinders equipped with no loss or low loss to fill mechanisms.

- Equipped with a handy pendant for easy control at the receiving vessel.

- Designed to use on adverse road conditions.

|

CODES: |

I.S.2825/ ASME SECTION-VIII DIV -1 & SMPV (U) RULES |

|

DESIGN PRESSURE: |

18 kg/cm² range. |

|

WORKING PRESSURE : |

6 kg to 15 Kg /Cm² range. |

|

DESIGN TEMPERATURE |

(-196°C 320°CF) |

|

CAPACITY: |

3000 Ltrs to 30000 Ltrs working volume. |

|

VAPOUR SPACE: |

5 to 7% of working capacity. |

|

DAILY EVAPORATION RATE (LIQUID 02) : |

1% maximum for smaller capacity and lesser with capacities increased. |

|

STANDARD DESIGNS: |

6000 Ltrs, 7000 Ltrs, 8000 Ltrs, 10000 Ltrs, 12000 Ltrs & 15000 Ltrs, Capacities with medium & High Pressures. |

Note:

- Inner vessel austenitic stainless steel, designed to EN 13530-2002. Outer vessel carbon steel designed to EN 13530-2.

- Specifications can change as per chassis selection and country road regulation.

- Tanks optimized for specific liquid and/or chassis available on request.

FILLING IN LIN DEWAR'S/DURA LIQUID CYLINDERS

Oxyplants India Pvt. Ltd. offers a full line of Dura liquid cylinder. The Dura liquid cylinder is designed to transport, store and deliver oxygen, nitrogen, argon, as a cryogenic liquid or gas. Dura cylinders are vacuum and super insulated vertical type liquid cylinders with in-built vaporizer which allows storage of cryogenic gases like oxygen, argon, nitrogen, medical oxygen at a very low temperature ranging From -183deg c To -196 deg c. The Dura Liquid Cylinders are manufactured in India As a design standard it is used CODE DOT4L, EN 13458 and ASME standards. Dura Cylinders are low pressure liquid cylinders provide the longest holding time, lowest evaporation rate, highest gas-withdrawal rate and best life-cycle cost.

Dura Liquid cylinders Tanks are produced to store liquid. The inner tank is made our of Stainless Steel 304L(SA240 TP304) & design code DOT4L. While the outer one is made out of stainless steel 304L (AISI304) & design code CGA-341,Ed.2007 . The common application for this liquid cylinder is to provide gas at pressures around 300 psi (20.7 BAR). The Dura Liquid Cylinder will build and maintain pressure at the control regulator setting of 300 psi (20.7 BAR). If the pressure exceeds 300 psi (20.7 BAR) the control regulator will supply gas from the tank vapor pressure. A continuous gas flow can be automatically provided from these cylinders.

Dura Liquid cylinders capacities range from 40 gallons to 60 gallons.

- Ideal for liquid nitrogen, oxygen, argon, CO2.

- Different sizes and pressures to suit your needs

- Stainless-steel construction, inside and out

- Thicker, dent-resistant outer shell

- Patented, durable, inner-vessel support system

- Heavy-duty footring and large diameter handling ring with four supports

- Combination Pressure Control Regulator

- Roto-CalTM Liquid Level Gauge System

- Combination pressure control regulator

- Calibrated micrometer adjusting screw

- Integral mounted dual regulator that controls pressure building and economizer function

- Eliminates copper piping and fittings

|

CODES: |

ASME Section - VIII DIV-1 / DOT 4L / EN125 / CGA-341,Ed.2007 / I.S. 2825 ETC WITH SMPV (U) Rules |

|

DESIGN PRESSURE: |

24.5 Kg/cm2 |

|

WORKING PRESSURE : |

1 Kg to 20 Kg/cm2 |

|

DESIGN TEMPERATURE |

-196oC (-320oF) + 40oC |

|

CAPACITY: |

150 ltrs to 250 ltrs working vol. |

|

VAPOUR SPACE: |

5 % of working capacity |

|

NER (Normal Evaporation Loss ) O2 |

STP Condition |

|

NER (Normal Evaporation Loss ) N2 |

STP Condition |

|

NER (Normal Evaporation Loss ) Ar |

STP Condition |

|

STANDARD DESIGNS: |

150 Ltrs, 200 Ltrs & 250 Ltrs Capacities with operating Pressures between 6 Kg/cm2g to 20 Kg/cm²g. |

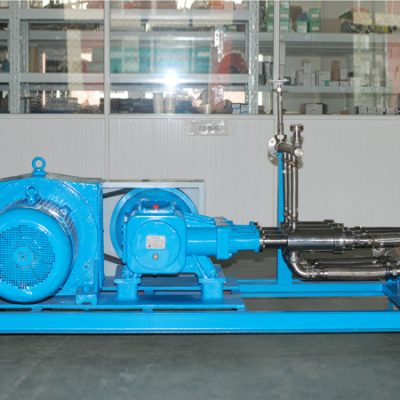

CRYOGENIC PUMPS

Oxyplants India Pvt. Ltd. offers a full line of Cryogenic pumps for Oxygen/Nitrogen/Argon Liquid from the cryogenic tank is compressed to high pressure in a cryogenic liquid pump. It is then vaporised in an ambient air vaporiser to produce gaseous oxygen/Nitrogen/Argon. The high-pressure gas then can pass into cylinders via the gas manifold or fed into a customer's product pipeline.

- The Cold End is Slanted upward by 10 Degrees to assist degassing of the Pump

- Provision to prevent accumulation of Gas in the Suction Chamber Prior to Startup and During Operation.

- Specially Designed Hat Seal and Special Seals remain Flexible even at extreme low temperature.

- Crank Drive have Connections for an Optional Nitrogen Purge

- Piston Head Made of Aluminum Bronze Allowing Safer Operation.

- The Flexible suction and return line sections are also slanted are made as short as possible so that pump can placed very closed to tank pod.

- Vacuum jacketed cold end helps minimizing heat Loss and reduce Liquid loss.

Technical Specification

|

Flow Rate |

20 Nm3 to 200 Nm3 / Hr |

|

Medium |

LOX, LIN, Argon |

|

Discharge Pressure |

150 Bar g |

|

Maximum suction pressure |

15 Bar g |

|

Design Temperature |

-196 |

|

Design Code |

ASME Sec VIII Div 1 |

AMBIENT AIR VAPORIZER

Oxyplants India Pvt. Ltd. supplies Atmospheric vaporizers for Liquid Nitrogen, Liquid Oxygen, and Liquid Argon and of various capacities ranging from 20 to 1000 NM3/ Hr. Ambient Air Vaporizer utilize convection as the heat transfer mechanism. Ambient air vaporizers use the relative "heat" of the atmosphere to derive the energy necessary for the vaporization of the liquid cryogen. Ambient vaporizers represent the most cost effective equipment to vaporize or re-gasify liquid cryogens. The vaporizers comprise a number of individual multi-finned aluminum heat transfer extruded elements lined with a high pressure retaining stainless steel tube. Extrusions are connected in series. Liners are hydrostatically expanded (tension bonded) into the extrusion element to ensure 100% contact and efficient heat transfer.

Vaporizers are designed and manufactured in accordance with the ASME Section VIII Div 1 latest edition pressure vessel code and the UBC and applicable sections of ANSI A 58.1. Vaporizers may be manufactured in compliance with any global pressure specification, such as ASME; TüV; PED; and other international codes.

The performance of ambient air vaporizers is subject to many factors. These include flow rate, duty cycle, ambient temperature, relative humidity, freeze period, altitude, wind, solar radiation, operating pressure and proximity to adjacent structures. The effects of average solar and wind conditions are not included in quoted ratings. Performance is based on mean ambient conditions of 70°F (21°C) and 70% relative humidity. Special conditions may vary considerably for a particular application, thereby affecting performance.

- Special end connections available

- Electro-polish for semiconductor industry applications

- Complete piping module assembly packages for vaporizer/piping installations

- Fog Reduction Module

- PE Certified Drawings

- California OSHPD approved designs

- Tank or trailer mounted designs

- Increased ground clearance further enhancing heat transfer by natural convection.

- High capacity fins measure 8 inches (203 mm) from tip to tip and provide high performance and longevity.

- Low pressure drop, full-bore passages in the elements provides more flow cross section.

- Heat transfer elements up to 40 ft (12 m) are available to meet a range of process demands. Standard assembly configurations and ratings are shown on the reverse side.

- MAWP – 580 psig* (40 bar g) for all aluminum construction.

Technical Specification

|

Volume |

20 Nm3 to 1000 Nm3 / Hr |

|

Design Pressure |

40 bar |

|

Design Temperature |

-196 o C |

|

Design Code |

ASME Sec VIII Div 1 ED 2004 AD 2005 |